AG-glass etching wastewater deammoniation project

Case description

AG-glass etching wastewater deammoniation

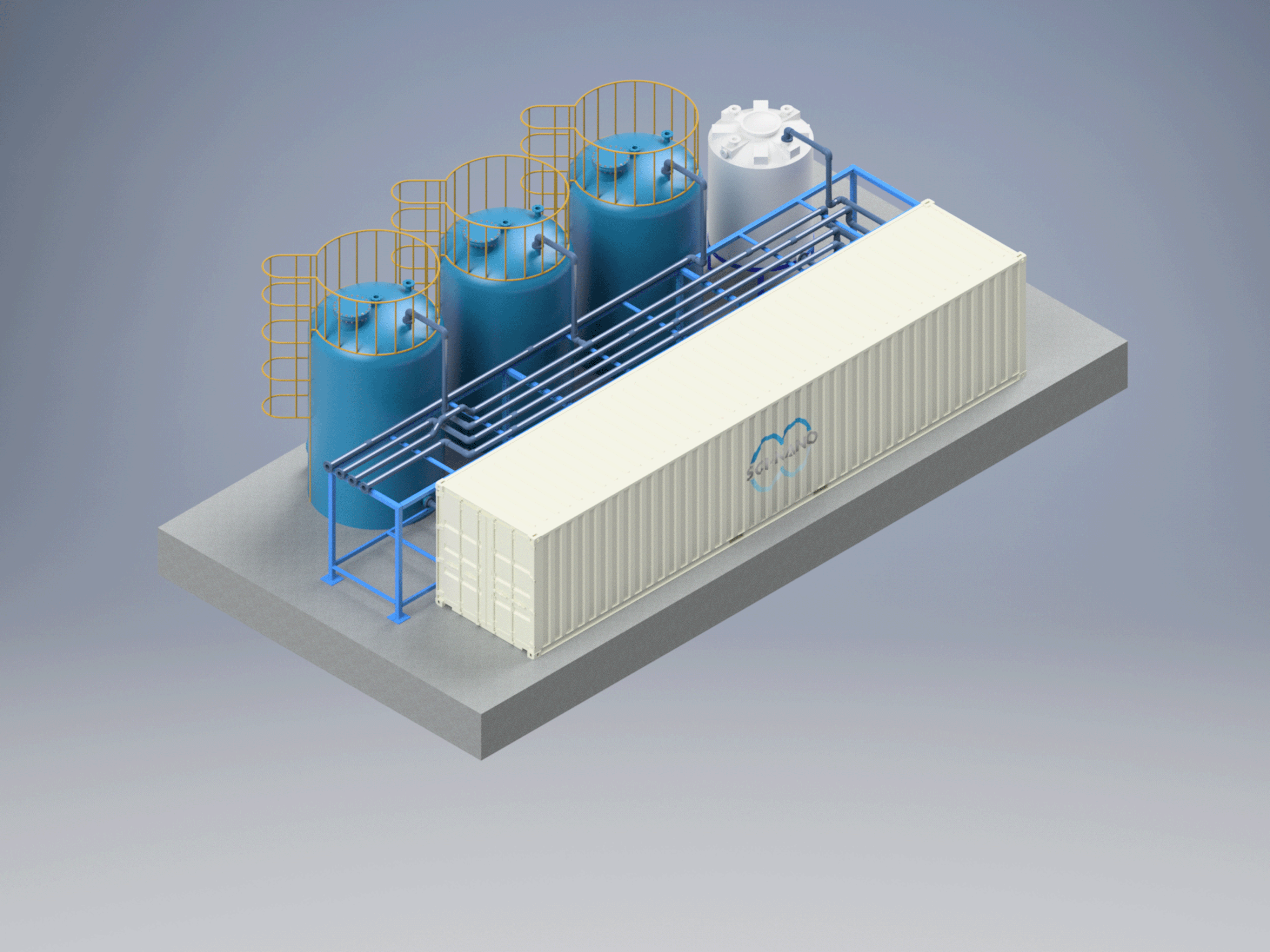

A certain optoelectronic glass production enterprise generates a large amount of high-ammonia nitrogen wastewater in the glass etching production process. The water quality and chemical cost are complex, the ammonia nitrogen content is high, and it contains a large amount of suspended solids and organic matter. In addition, the water quality and water volume often fluctuate greatly. In response to the above challenges, SCINANO, with its professional technical advantages and combined with the actual situation of the owner, provided a design solution for treating high-ammonia nitrogen wastewater with membrane deamination method (TMCS technology), helping the company to achieve efficient and stable etching wastewater discharge.

Process Flow

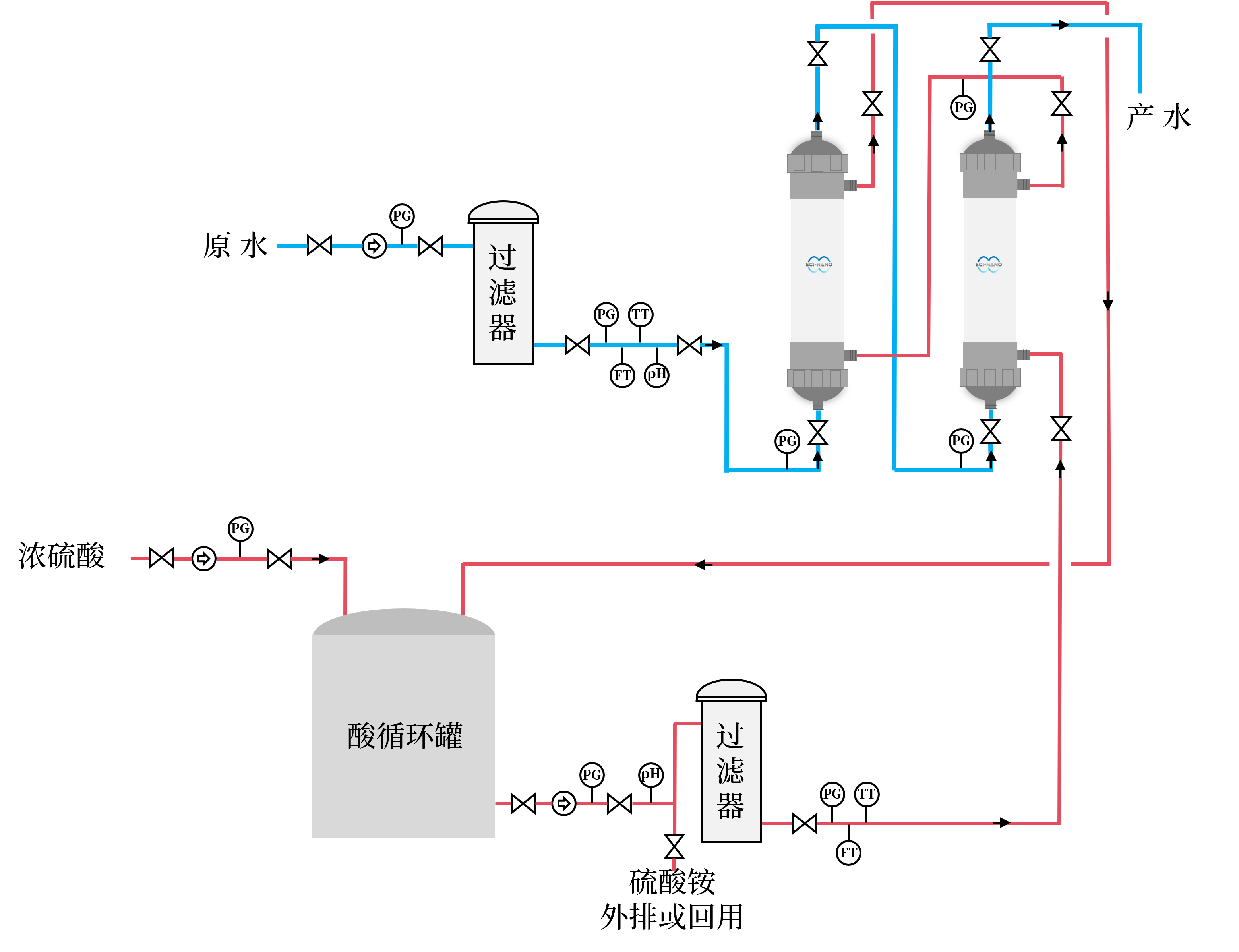

The process (TMCS technology) combining pretreatment with a two-stage PTFE deammoniation membrane system is adopted.

Process Principle

By adjusting the pH value of wastewater, free ammonia is generated in wastewater. Free ammonia (NH3) in wastewater can pass through the micropores on the surface of hollow fiber membrane, reach the outside of hollow fiber membrane and react with dilute sulfuric acid to generate ammonium sulfate, thereby achieving the purpose of removing ammonia nitrogen and ensuring the stability of the project's effluent.

Operation Status

Water Volume:240t/d

Influent Water Quality: ammonia nitrogen concentration is 500-8000㎎/L

Effluent Water Quality: ammonia nitrogen concentration ≤100㎎/L

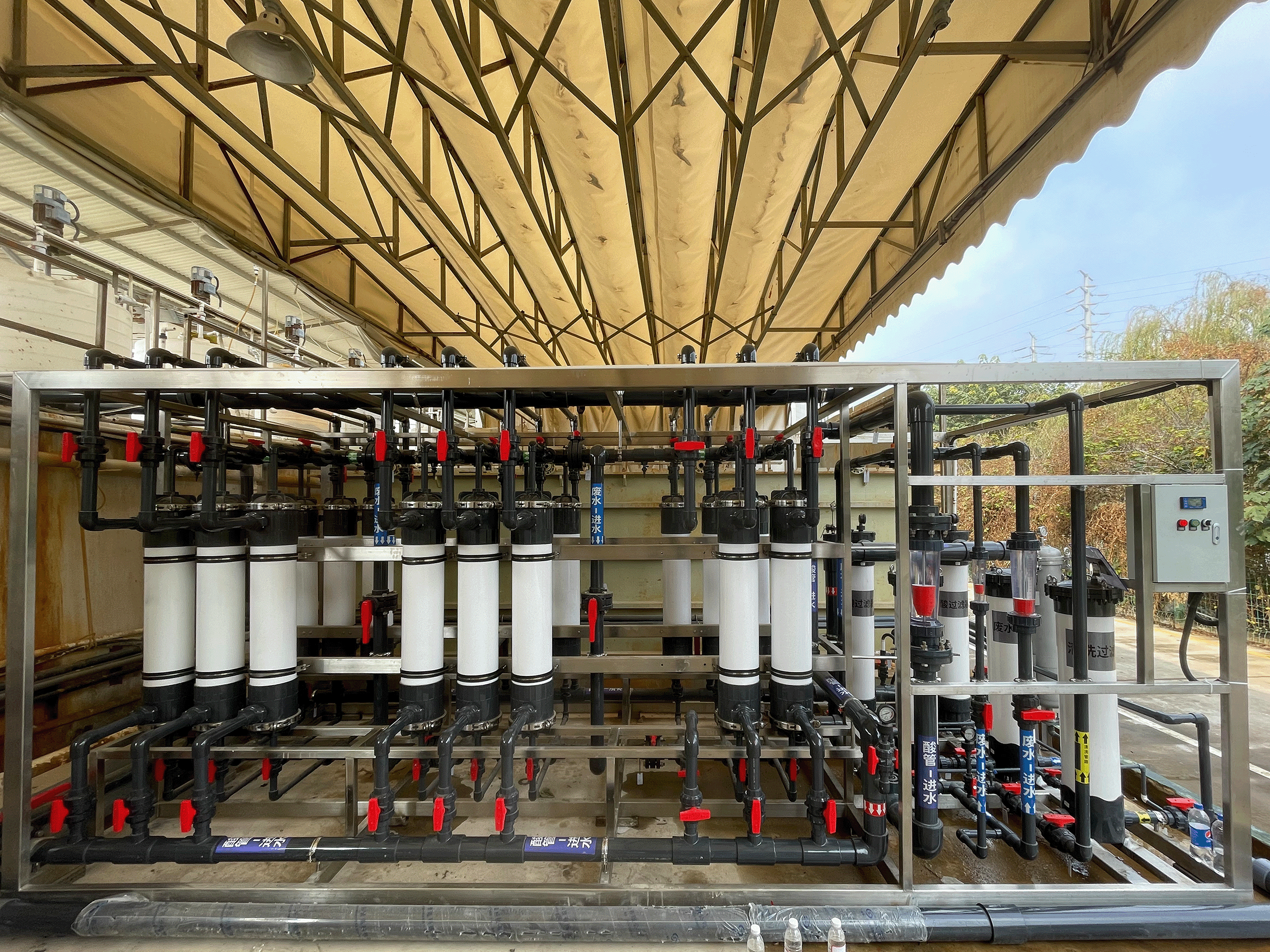

On-site Pictures

Key words:

Previous Page

Supporting Products

Welcome your message consultation