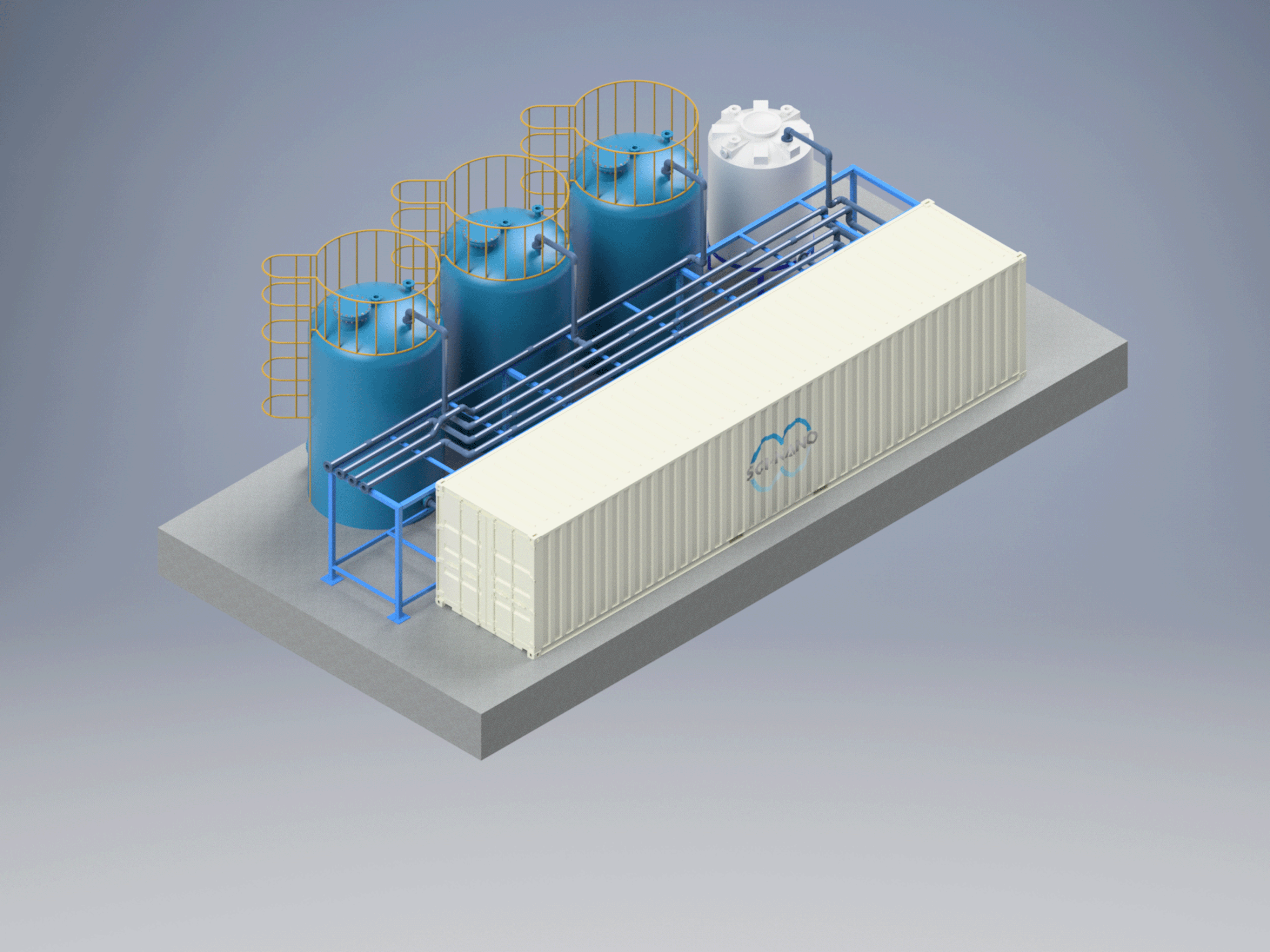

Pigment wastewater deammoniation project

Case description

Project Background

A pigment chemical plant in Shandong, China, produces hundreds of tons of high-ammonia nitrogen wastewater every day in the pigment production process, with ammonia nitrogen concentration ranging from 1600 to 1800 mg per liter. Previously, the plant used traditional biological treatment methods to treat wastewater. However, after the expansion, the discharged ammonia nitrogen wastewater exceeded the upper limit of the biochemical treatment system's processing capacity, causing the entire treatment system to be paralyzed.

After a comprehensive evaluation of various ammonia nitrogen wastewater treatment solutions, the owner decided to use After a comprehensive evaluation of various ammonia nitrogen wastewater treatment solutions, the owner decided to use the membrane deammoniation method (TMCS technology) designed by SCINANO to treat high-ammonia nitrogen wastewater after analysis and research.

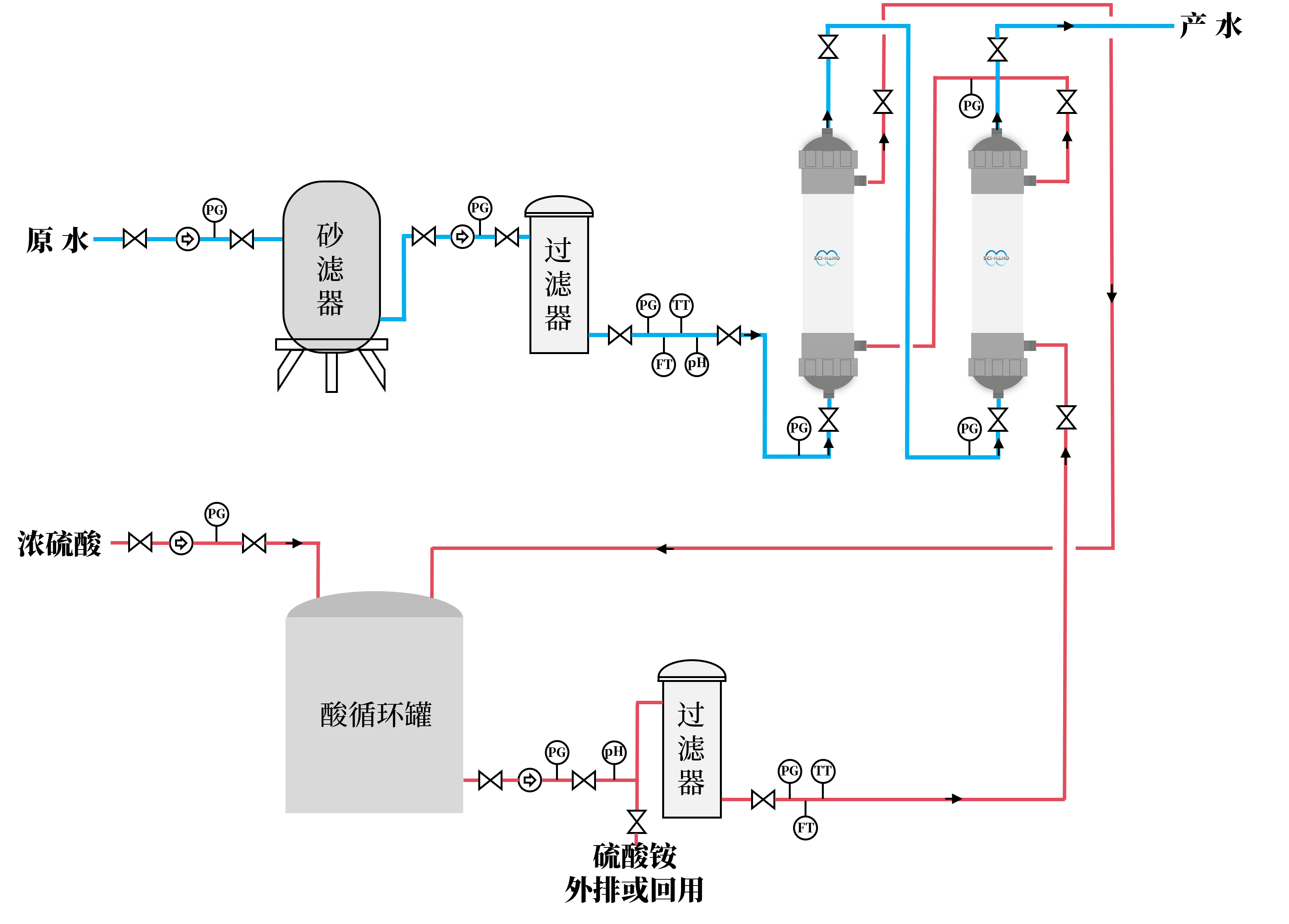

Process Flow

The process (TMCS technology) combining pretreatment with a two-stage PTFE deammoniation membrane system is adopted.

Process Principle

By adjusting the pH value of wastewater, free ammonia is generated in wastewater. Free ammonia (NH3) in wastewater can pass through the micropores on the surface of hollow fiber membrane, reach the outside of hollow fiber membrane and react with dilute sulfuric acid to generate ammonium sulfate, thereby achieving the purpose of removing ammonia nitrogen and ensuring the stability of the project's effluent.

Operation Status

Water Volume:100t/d

Influent Water Quality: ammonia nitrogen concentration is 1600-1800㎎/L

Effluent Water Quality: ammonia nitrogen concentration ≤45㎎/L

On-site Pictures

Key words:

Previous Page

Previous Page

Supporting Products

Welcome your message consultation