Ammonia Removal Principle of Sulfuric Acid with Ammonia Removal Membrane

Release time:

2024-06-19

The ammonia removal membrane technology has the following advantages in removing ammonia nitrogen: high efficiency and stable effluent quality, compact and flexible design, environmental protection and no secondary pollution, high automation and easy operation, economic recovery of by-products and good pollution resistance and cleanliness, etc.

In recent years, the environmental pollution caused by wastewater containing ammonia nitrogen is becoming more and more serious. Excessive discharge of ammonia nitrogen will lead to eutrophication, break the balance of the ecosystem, and produce a variety of environmental problems, posing a serious threat to ecological security.

In the field of environmental protection, how to effectively treat ammonia nitrogen wastewater is a major focus. With the progress of water treatment technology, especially the popularization of membrane technology, membrane-based deamination technology has also received the attention and practice of experts in the industry.

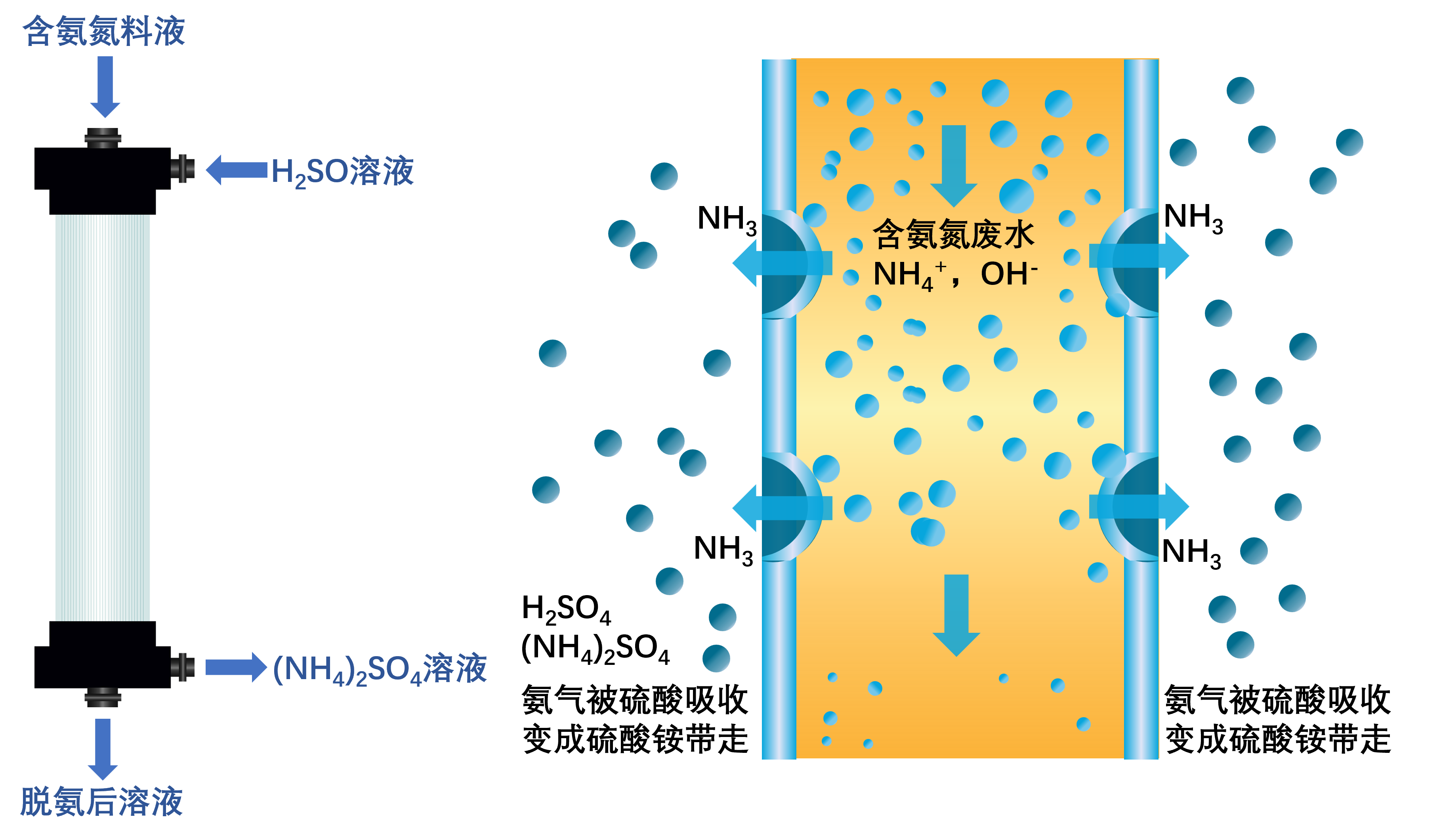

Ammonia removal membrane technology is an innovative separation process that combines membrane separation with traditional stripping and absorption methods. In this process, the wastewater containing ammonia nitrogen flows on the shell side of the membrane module (outside of the hollow fiber membrane filaments), and the sulfuric acid absorbing liquid flows on the tube side of the membrane module (inside of the hollow fiber).

There is a dissociation equilibrium of ammonia nitrogen in water: NH4 OH and NH3 H2O. When the pH increases or the temperature rises in the wastewater, the equilibrium will shift to the right and NH4 will become free gaseous NH3.

Under certain conditions, such as an increase in pH or temperature, the dissociation equilibrium of ammonia nitrogen in water will shift in the direction of ammonia gas generation, so that ammonium ions are converted into gaseous ammonia. The dehydrogenation membrane takes advantage of this characteristic, and its hydrophobic PTFE hollow fiber membrane can prevent water from passing through and only allows ammonia to pass through. In this way, the ammonia nitrogen in the wastewater is converted into a gaseous state, passes through the membrane filament to be absorbed by sulfuric acid, and is converted into an ionic ammonium ion again.

Under the condition that the pH value is higher than 10 and the temperature is 35~50 ℃, the ammonium ion will be continuously converted into ammonia gas and absorbed by the absorption liquid, so as to realize the deamination. At the same time, ammonium sulfate solution can be recycled, which not only reduces pollution, but also realizes the recovery of resources.

The characteristics of ammonia removal membrane technology in the removal of ammonia nitrogen include:

(1) High efficiency and stable effluent quality: The use of ammonia removal membranes can achieve a high ammonia nitrogen removal rate and maintain a relatively stable effluent quality.

(2) Compact and flexible design: The device adopts a modular design, which not only occupies a small space, but also facilitates relocation or expansion of capacity.

(3) Environmental protection and no secondary pollution: The entire treatment equipment is a closed system, which avoids the leakage of pollutants, so there is no secondary pollution problem.

(4) Highly automated and easy to operate: The deamination membrane device has a high degree of automation, which makes the operation process simple and convenient.

(5) The economy of recycling by-products: The generated ammonium sulfate can be effectively recovered and utilized, and has certain economic value.

(6) Good pollution resistance and cleanliness: The deamination membrane has strong anti-pollution ability and is easy to clean and maintain.

Latest News