Power plant reverse osmosis concentrated water-low temperature membrane distillation

Case description

Power plant reverse osmosis concentrated water-low temperature membrane distillation

During the power generation period of a power plant, a large amount of sewage will be generated, which will form RO concentrated water after the treatment system. It is now planned to use a membrane distillation system to concentrate it. The specific requirements are as follows: under the working condition that the inlet water hardness is less than 1500mg/L (calculated as CaCO₃), the downstream membrane system shall not have scaling phenomenon, and there is still no scaling when the treated water concentration ratio reaches 4 times; it can adapt to water quality with a pH value in the range of 3.0-10.0; ensure that the membrane distillation device is cleaned no more than 2 times a year. The recovery rate of the low-temperature membrane distillation system shall not be less than 80%, the water production shall not be less than 80L per hour, and the conductivity of the produced water shall be controlled within 20μS/cm. In terms of heat source, thermal power waste heat boiler or gas boiler sewage can be selected, and electric auxiliary heating can be considered as a backup.

Process Flow

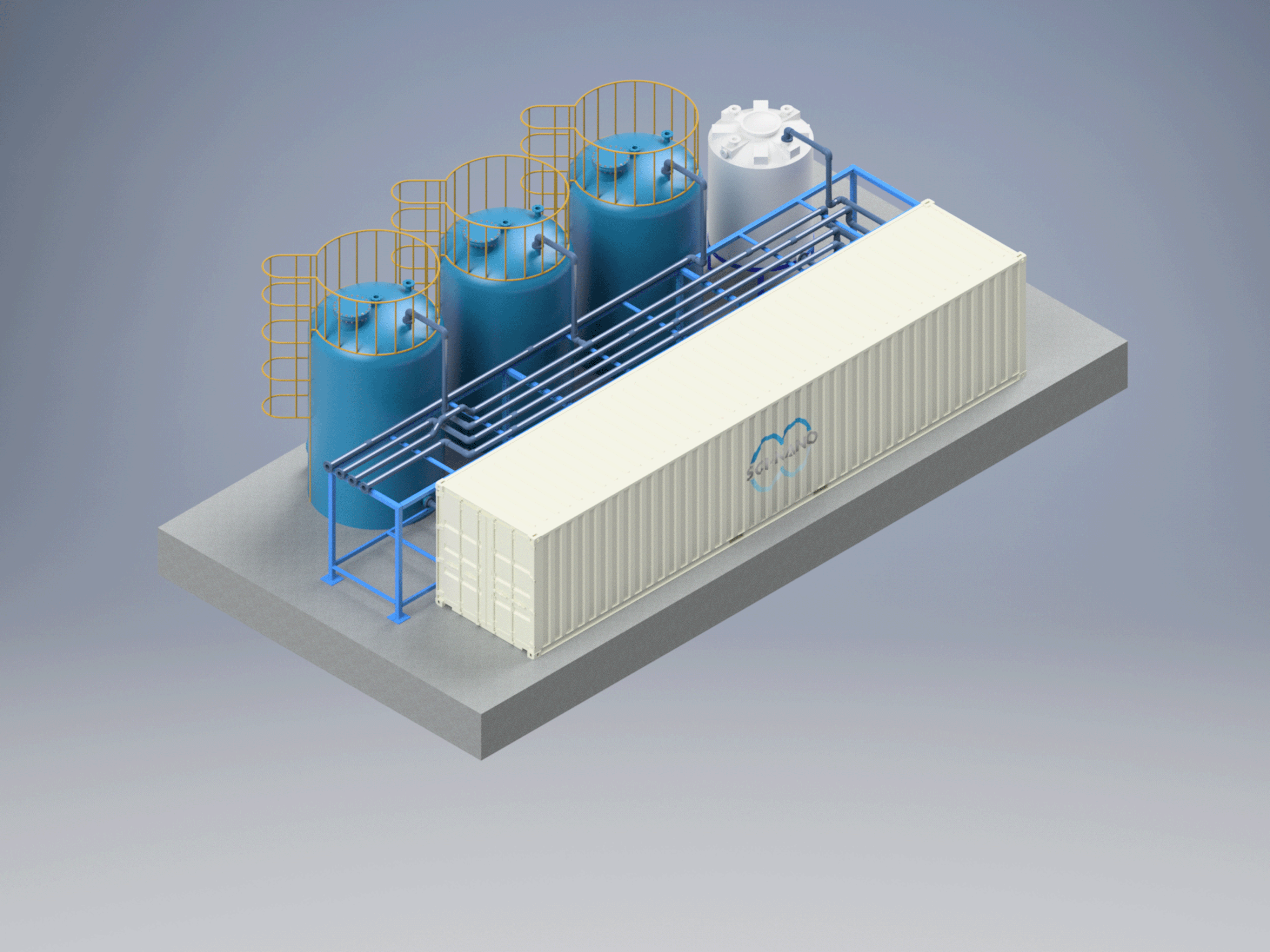

It uses weak acid anion resin + coal-catalyst alloy + security filter + PTFE membrane distillation components.

Process Principle

The separation interface is constructed using PTFE hydrophobic hollow fiber membranes, and the steam pressure difference on both sides of the membrane is used as the driving force to allow the steam on the hot side to pass through the membrane pores into the cold side and condense, thereby achieving separation, purification or concentration of the mixture.

Operation Status

72 degrees Celsius circulation, close the raw water inlet valve (no raw water enters the system).

Initial water volume: 150L

Half-hour condensed water volume: 42L

Water tank water volume at the end: 95L

Concentrated water discharge volume: 16L/h

Therefore, at 72℃, the recovery rate of the membrane distillation equipment is: 89%

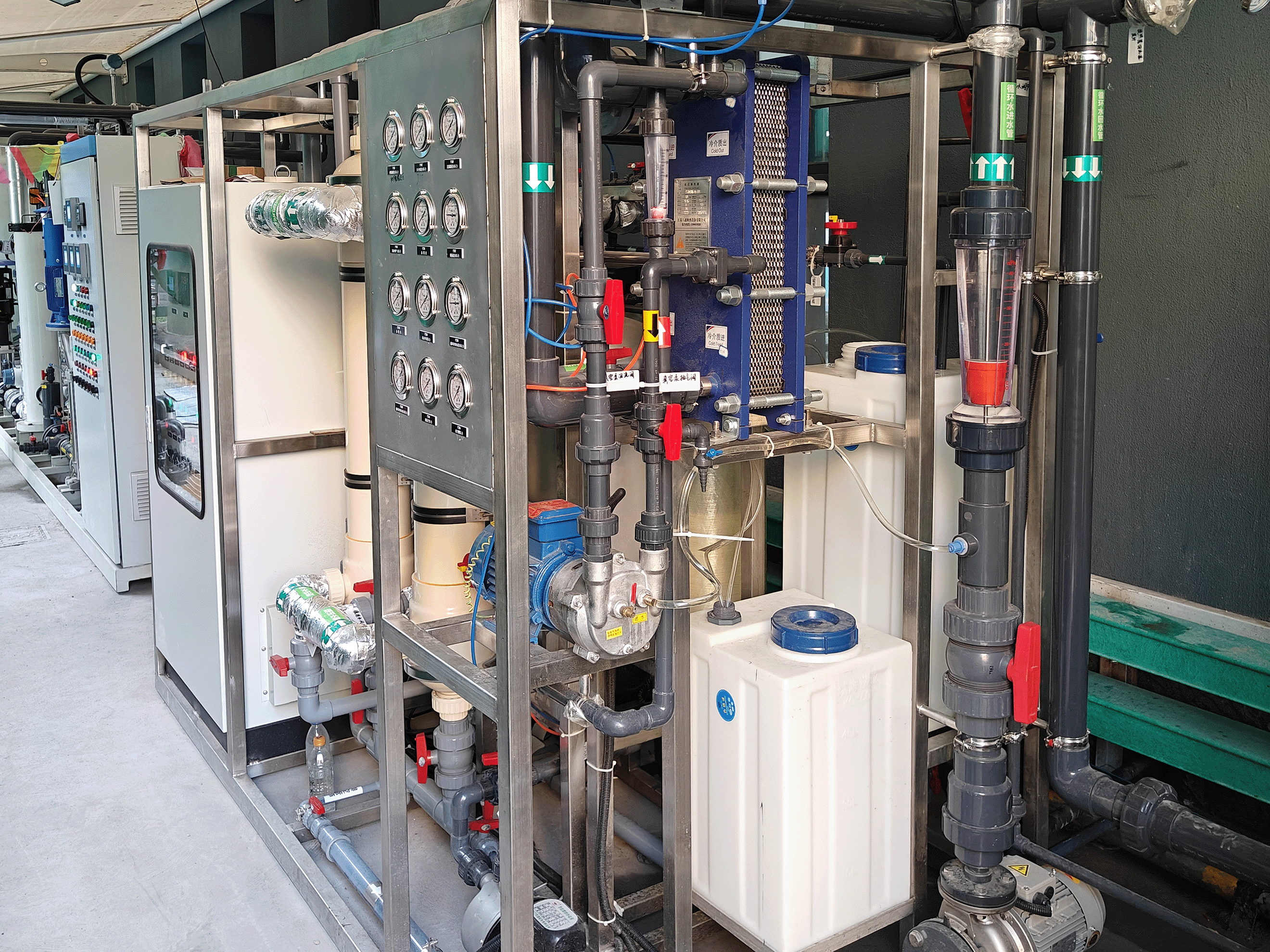

On-site Pictures

Key words:

Supporting Products

Welcome your message consultation